“High standard, high precision, zero defect”

“Honesty and Practicality, Persevering Unremittingly, Teamwork Spirit, Achieving Greatness”

Ultrasonic welding mold

Ultrasonic welding mold

Ultrasonic welding mold

Ultrasonic welding mold

Ultrasonic welding mold

Ultrasonic welding mold

We have 10 years of work experience and an experienced R&D team, which can develop and produce products according to drawings or samples provided by customers.

We have our own production workshop, skilled workers and mature parts supply chain, with low production cost and good quality.

We have industry-leading production technology and manufacturing experience, product quality is stable and reliable.

The product is committed to the research and development and application of industrial plastic welding technology, and a production-oriented enterprise that produces various welding molds.

Our annual output exceeds 3000 sets of machines and 5000 sets of molds, which can meet the needs of customers with different purchases.

We provide customized services for customers with different needs, the quality meets the high-end market, and the products meet international standards.

Customers send drawings, samples or specific requirements

We will according to the customer's drawings, samples or requirements, do the quotation scheme, sent to the customer for confirmation

After the two parties discuss the plan, the details are determined and the contract is signed

The customer confirms the quotation, and the advance payment is 30% of the purchase price. The payment term is T/T

Design, drawing production

After the completion of equipment or mold, equipment debugging or mold sample

For small pieces, sample can be sent to customers for confirmation. For large pieces, on-site confirmation or live video confirmation can be made

Inspectors inspect equipment or molds and pack them into boxes

According to customer specified delivery, customer pay balance payment

After the equipment arrives at the customer's factory, the technician will debug the equipment on site and teach the use method and matters needing attention. After the mold arrives at the customer's factory, the technician will install and test the mold on site (under special circumstances, audio or video guidance for installation).

A plastic welding machine is a device that is used to join or repair plastic parts. Plastic welding ...

Ultrasonic Plastic Welding machine is mechanical vibration energy that operates at frequencies above...

1. Improve the joint of ultrasonic plastic welding machine Wholesale Ultrasonic Plastic Welding mach...

Generally speaking, an Wholesale Ultrasonic Plastic Welding Machine Factory is a component that cond...

Replacement welding steps of China Hot Plate Plastic Welding Machine equipment factory 1. First, che...

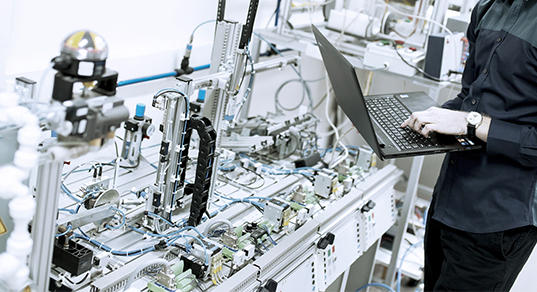

In addition to standard equipment, Non-Standard Automation Machines manufacturers must produce non-s...

Non-Standard Automation Machines are a kind of manufacturing equipment that uses processes and techn...

Ultrasonic horns are metal bars with a tapering end that are commonly used to increase the amplitude...