Ultrasonic Plastic Welding machine works: We know that the correct physical definition of a wave is: the transmission of vibration in an object forms a wave. The formation of such waves must have two conditions: one is the vibration source, and the other is the propagation medium. The classification of waves is generally as follows: First, they are classified according to the vibration direction and propagation direction. When the direction of vibration is perpendicular to the direction of propagation, it is called a shear wave. When the vibration direction is consistent with the propagation direction, it is called longitudinal wave. Second, according to frequency classification, we know that the sensitive hearing range of the human ear is 20HZ-20000HZ, so the waves within this range are called sound waves. Waves below this range are called infrasound waves, and waves above this range are called ultrasonic waves.

Wave propagation in an object mainly has the following parameters: one is the speed V, the other is the frequency F, and the third is the wavelength λ. The relationship between the three is as follows: V=F.λ. The speed of wave propagation in the same material is constant, so the wavelength is different at different frequencies. In addition, it is also necessary to consider that the wave propagation in the object always has attenuation. The longer the propagation distance, the more severe the energy attenuation, which is also considered in ultrasonic processing.

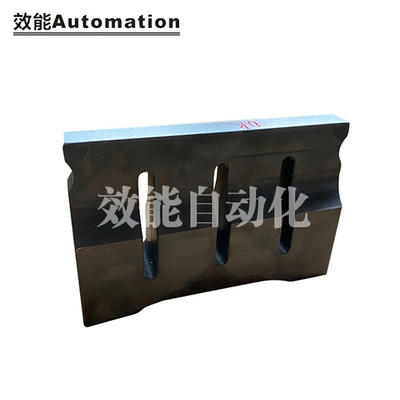

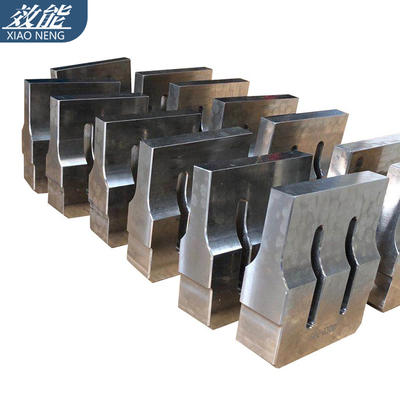

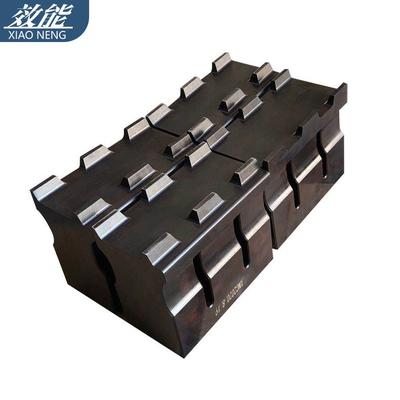

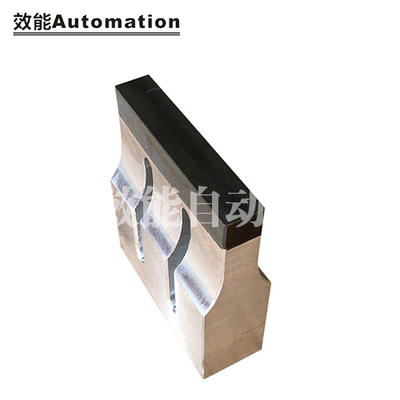

1. The application principle of ultrasonic wave in plastic processing: the ultrasonic wave used in plastic processing has several working frequencies of 15KHZ, 18KHZ, 20KHZ and 40KHZ. The principle is to use the crest position of the longitudinal wave to transmit the amplitude to the gap of the plastic part. Under the condition of pressure, the molecules of the two plastic parts or other parts in contact with the plastic part collide with each other to melt, so that the plastic at the contact position is fused to achieve processing purpose.

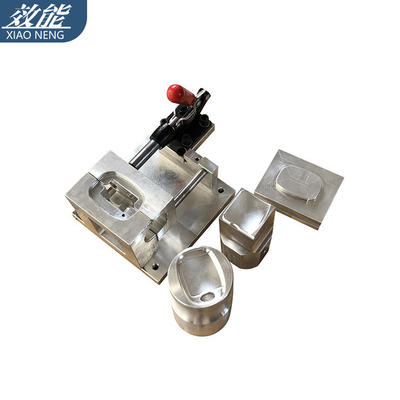

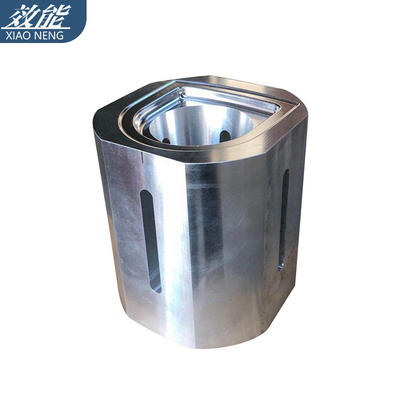

2. Components and principles of Ultrasonic Plastic Welding machine

Ultrasonic Plastic Welding machine is mainly composed of the following parts: generator, pneumatic part, program control part, transducer part. The main function of the generator is to convert the power frequency of 50HZ into high-voltage waves of high frequency (such as 20KHZ) using electronic circuits.

The main function of the pneumatic part is to complete the pressure work such as pressurization and pressure maintenance during the processing process. The program control part controls the workflow of the entire machine to achieve consistent processing results. The transducer part converts the high-voltage radio waves generated by the generator into mechanical vibrations, which are transmitted and amplified to reach the machined surface.

英语

英语 日语

日语 中文简体

中文简体