Applies to:

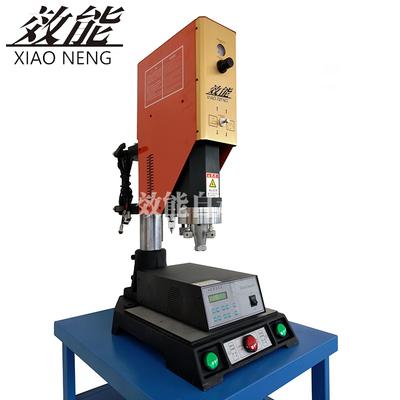

It is mainly used for plastic products that are not suitable for ultrasonic plastic welding, such as extra-large products, soft plastics, irregular shapes, and require leak-proof and air-tight specifications. Its advantages are firmness after welding, high stability, 100% water leakage and air leakage effect, and very reliable. Suitable for PP, PC, ABS nylon, thermoplastics, and plastics containing glass fiber, etc.

Working characteristics: fast..... each welding time is 0.001-9.99 seconds

Strength... can withstand large pulling forces. high pressure.

Quality...no water leakage, air-tight welding, no damage to plastic parts when welding.

Economical...no screws or glue, less labor and low cost.

Technical features:

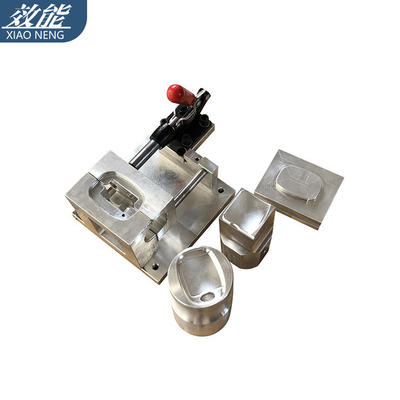

Horn stencil welding

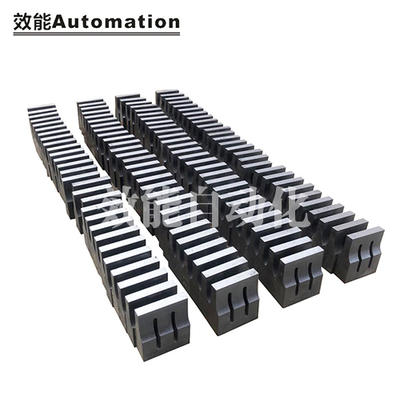

PP, PC, nylon, glass fiber... engineering plastic welding

100% watertight, airtight, high stability

800KHz high frequency induction heating, extremely effective

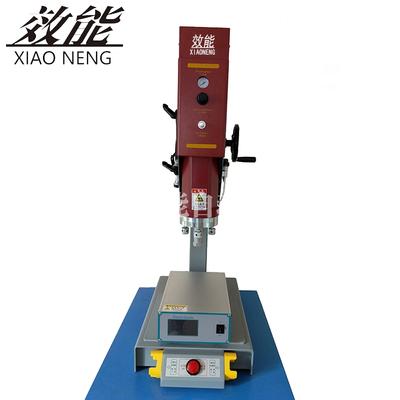

Model: DH-15KW/DH-25KW/DH-35KW

Output power: Output power: 15KW/25KW/35KW

Output frequency: Output Fre: 800KHz

Input power Input power: AC380KV.3P

Press method: Pneumatic

Stroke: 150mm

Low Table.size: 600L×400W(mm)

Cooling water flow/pressure Vol.of water: 8L/min, 1.5Kgf/cm2

Application example:

Household appliances-electric iron water storage tank, electric hot water bottle, leaking device, toilet board, stainless steel thermos display ruler, agitator, steam iron water storage tank, water pipe welding, electric hair dryer, printer carbon powder box, vacuum cleaner water storage tank.

Audio box-speaker steel mesh, screw welding, screw cap.

Automotive industry-automotive taillights, batteries, fuel tanks, water storage tanks, filters, automotive water tank oil pans, etc.

英语

英语 日语

日语 中文简体

中文简体