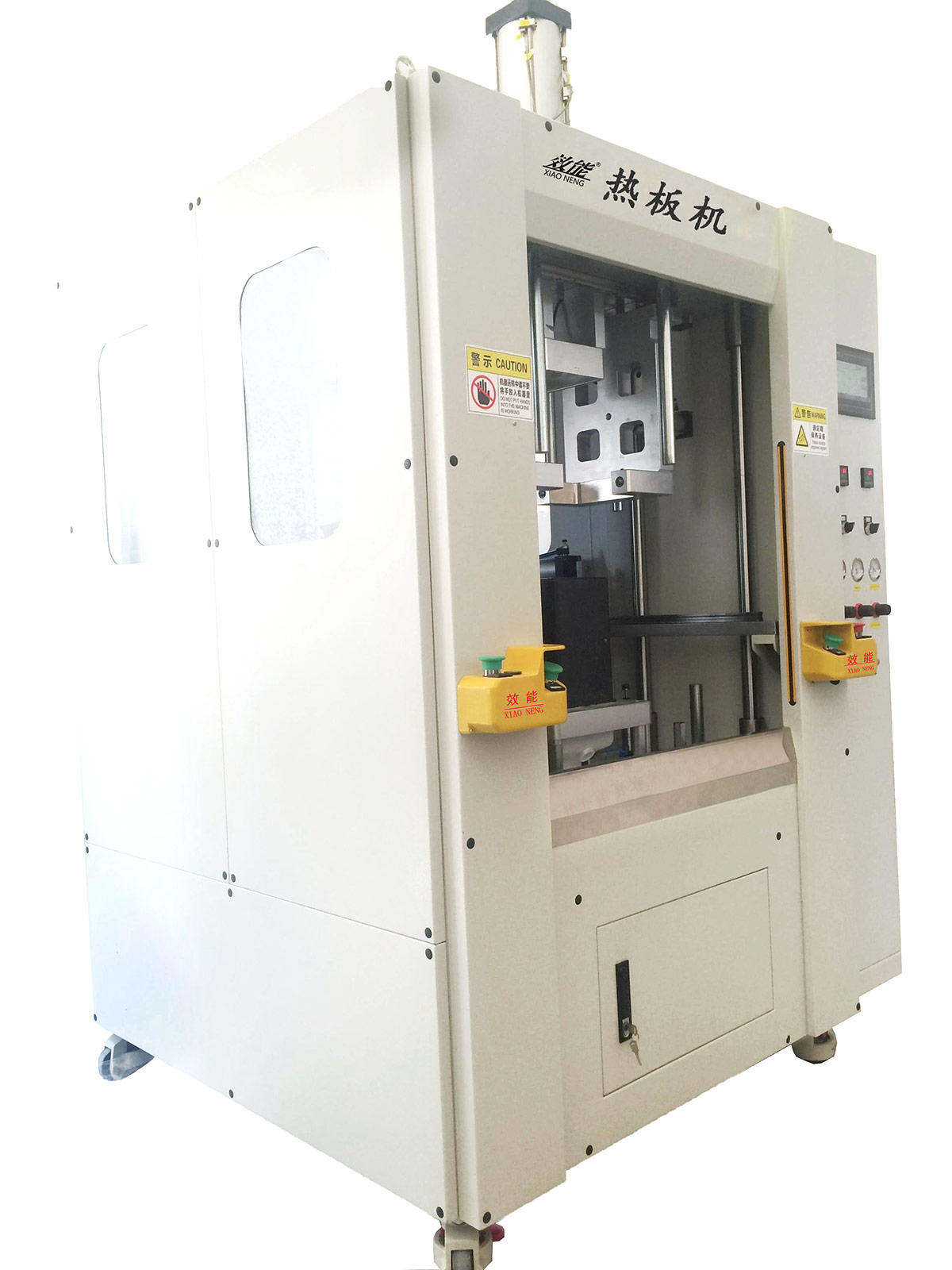

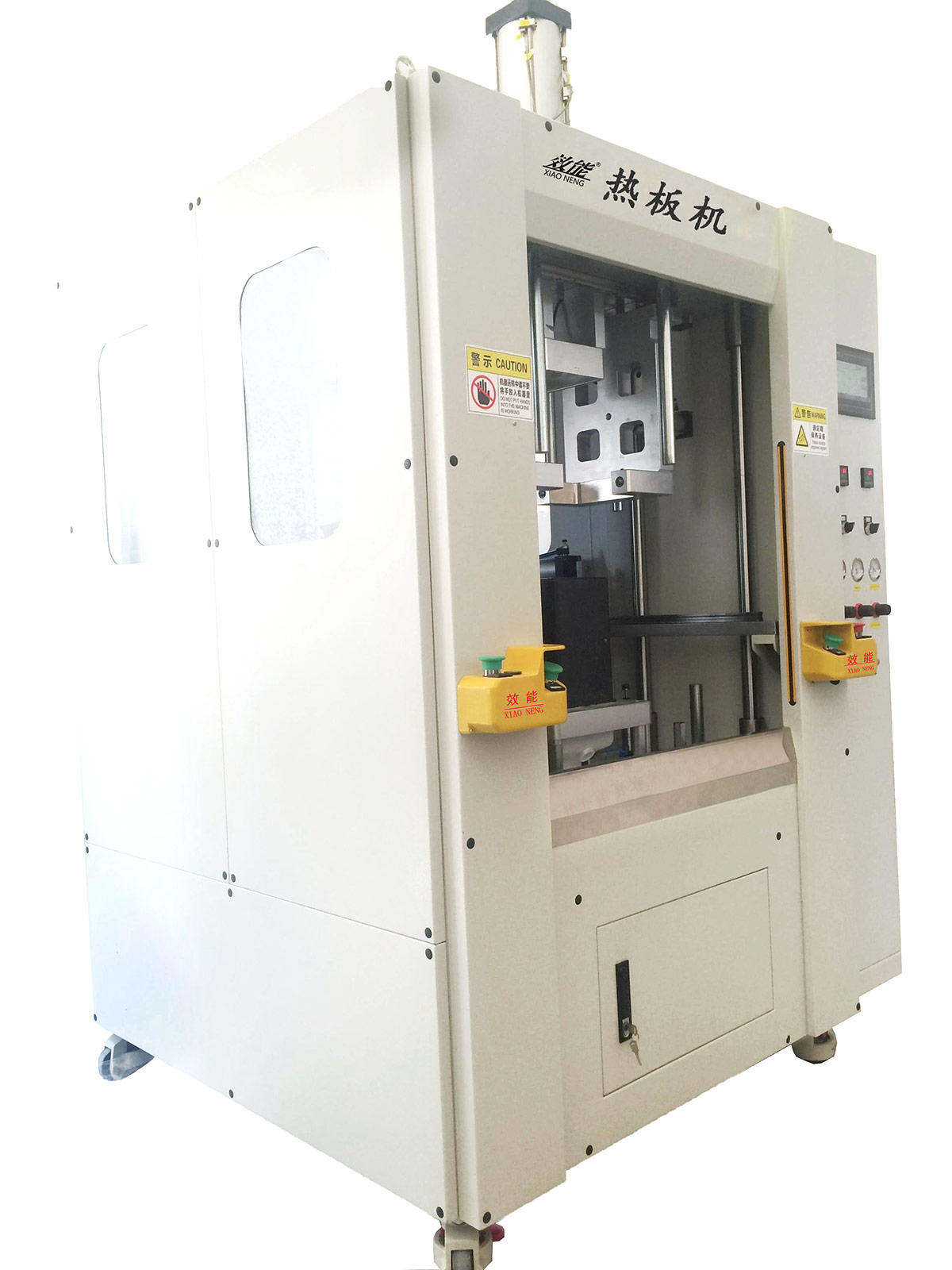

Brief introduction of efficiency 600 hot plate machine:

|

Appearance size of equipment (length*width*height)

|

1500*1400*2200mm

|

|

Maximum welding area

|

750*450mm

|

|

Voltage

|

380V

|

|

Heating power

|

1-15KW

|

|

Mold opening stroke

|

950mm

|

|

weight

|

700KG

|

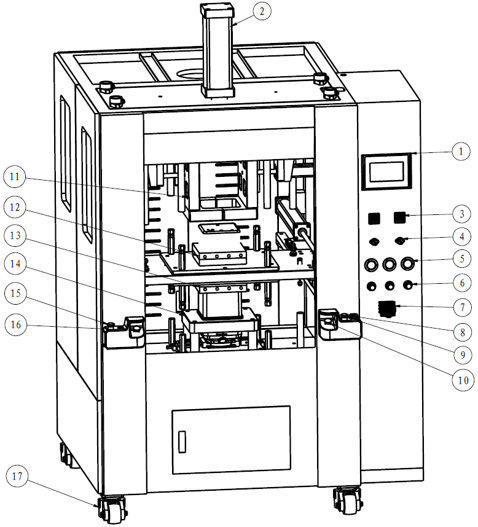

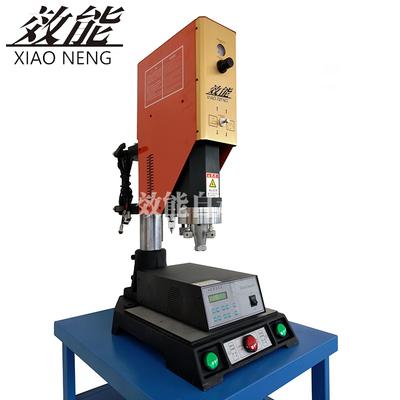

Performance 600 appearance introduction:

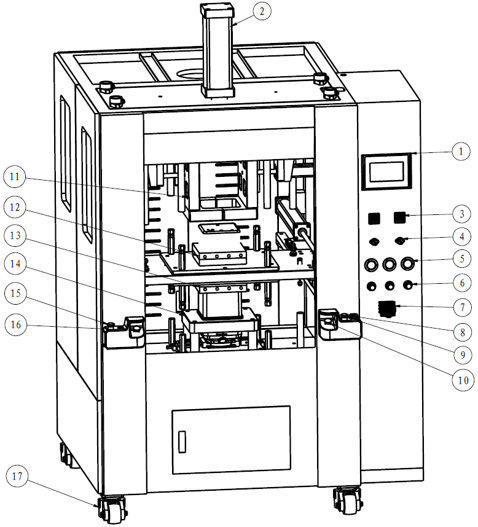

①Man-machine interface: control the entire equipment parameters;

②Upper mold cylinder: control the upper mold transmission device;

③Temperature controller: control the temperature of the heating plate, respectively on the upper left and lower right;

④Temperature controller switch: control the temperature controller switch, respectively upper left and lower right;

⑤Barometer: display the current air pressure of the upper, lower and clamps from left to right;

⑥Pressure regulating valve: control the current air pressure of the upper, lower and clamps respectively from left to right;

⑦Total power switch: to control the total power of the equipment;

⑧Emergency stop: Pause button in case of abnormal equipment;

⑨ Mold fixture button: manual mode, control the lower mold fixture;

⑩Start button: the equipment is working normally and must run at the same time as "15";

⑪Upper mold: upper product fixing device;

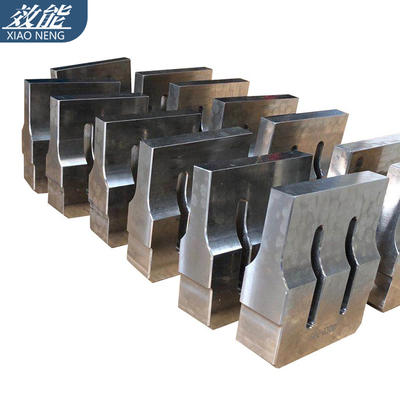

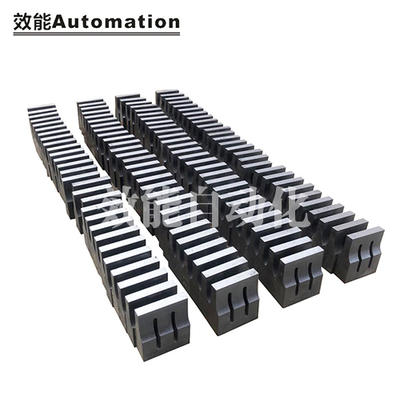

⑫Upper heating mold: heating the upper product mold:

⑬Lower heating mold: heating the lower product mold:

⑭Lower mold: small product fixing device;

⑮Start button: the equipment is working normally and must run at the same time as "10";

⑯Upper mold fixture button: control the upper mold fixture;

⑰Casters: fixed equipment device, can be used to adjust the height of the equipment;

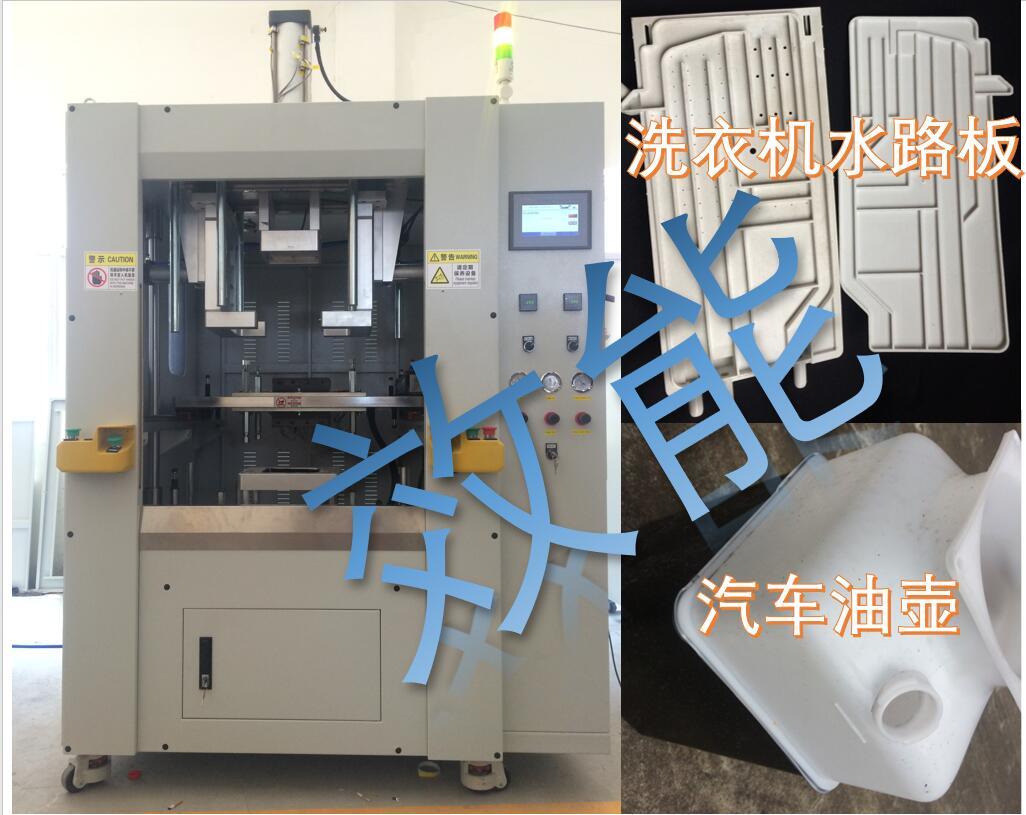

3D renderings of efficiency 600 hot plate machine

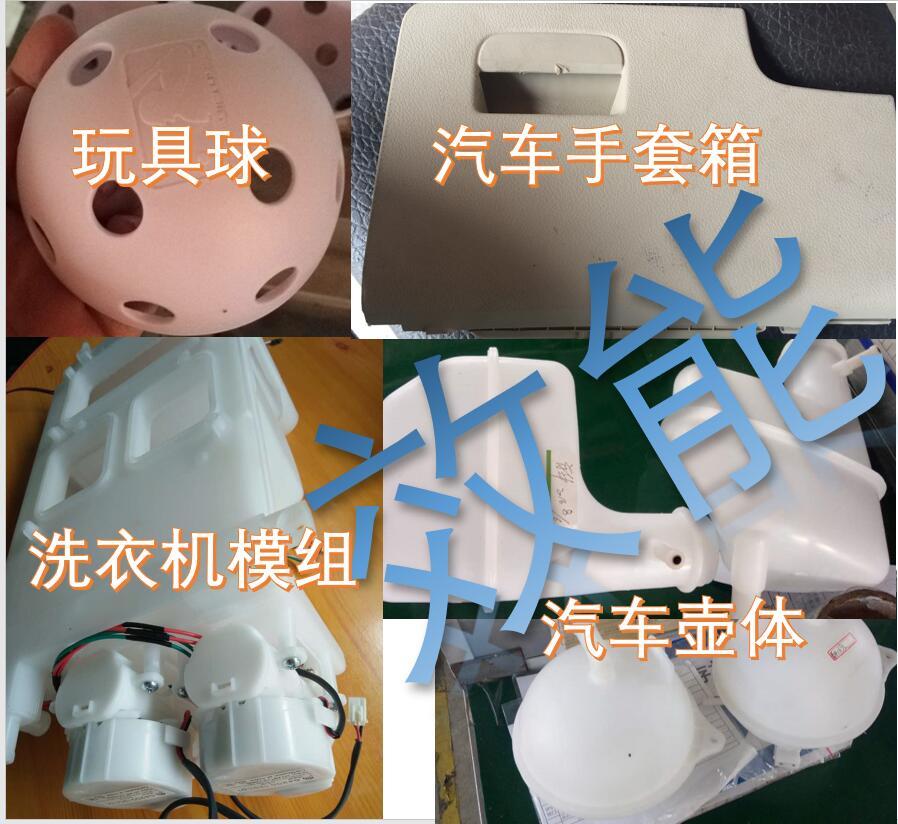

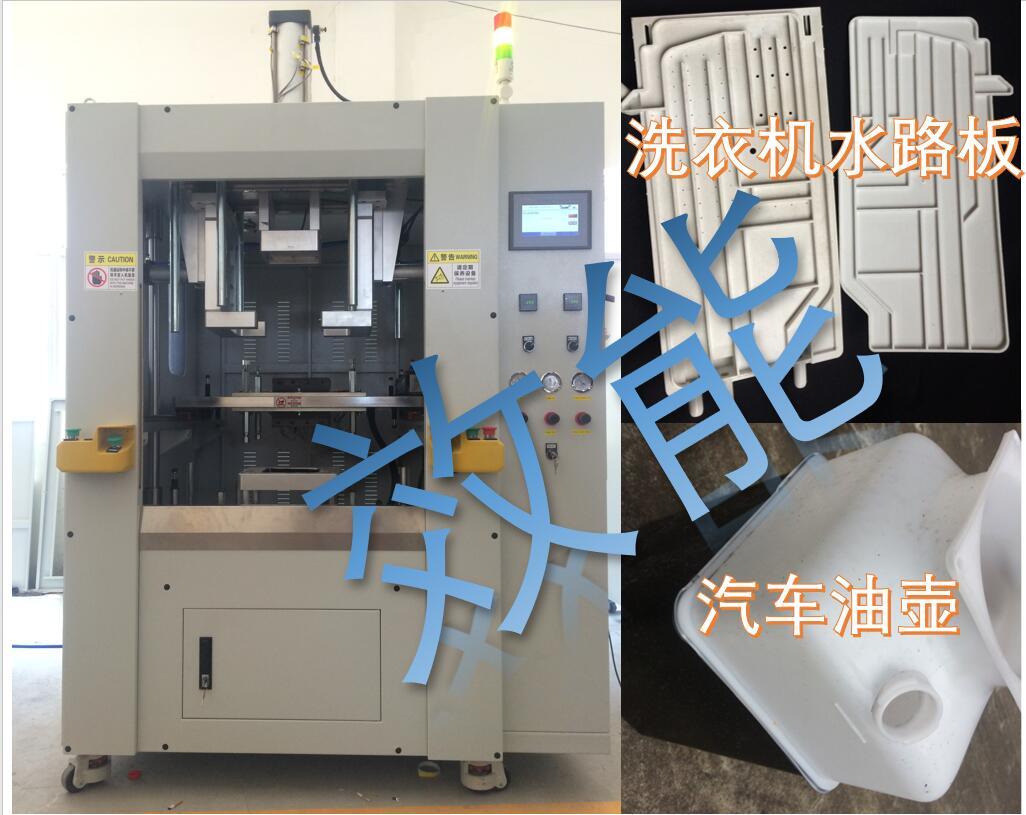

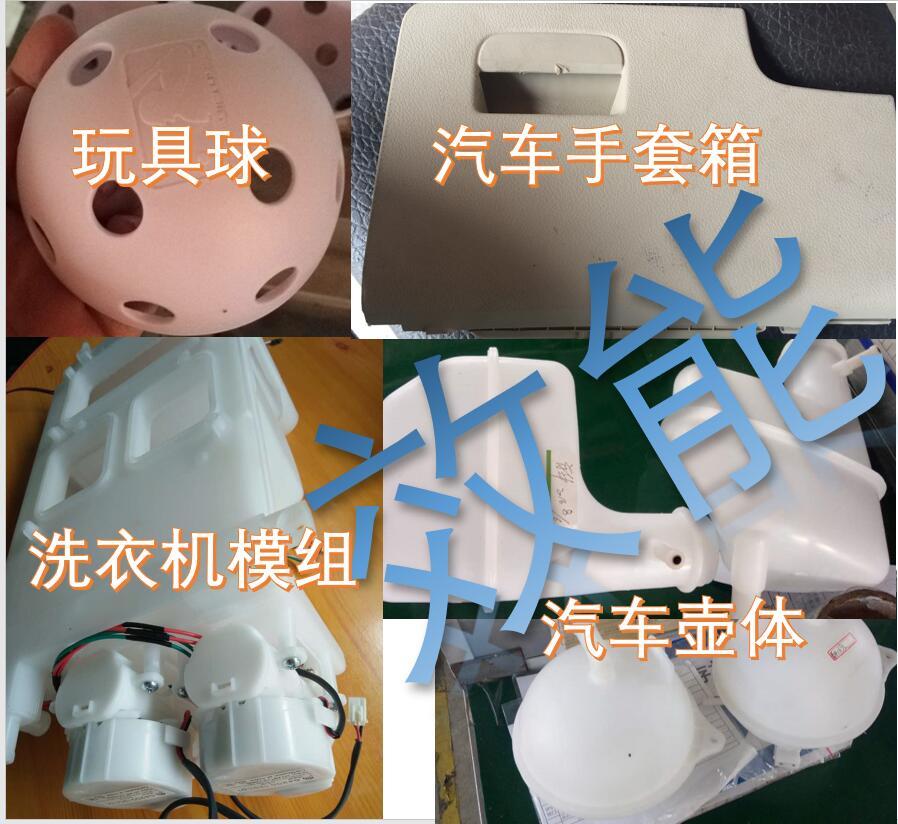

Hot plate welding uses the principle of electrothermal melting, prepares to control temperature changes, and is equipped with perfect mechanical devices to achieve perfect welding. It makes up for the insufficiency of ultrasonic welding machines for welding large and special plastic workpieces. It is mainly used for PP, PE and other thermoplastic materials and welds. Welding of large and complex plastic workpieces.

Features of efficiency 600 hot plate welding:

1. The equipment series are divided into vertical or parallel hot plate devices.

2. The transmission system will be driven by qigong, hydraulic drive or servo motor.

3. Smart design to meet production needs.

Advantages of the efficiency 600 hot plate welding machine:

1. It can be applied to workpieces of different sizes without area limitation.

2. It can be applied to any welding surface without special requirements.

3. The welding surface can allow plastic margin compensation, and the welding strength is guaranteed.

4. According to the needs of various materials, the welding procedure can be adjusted.

Hot plate welding machine equipment specifications:

1. The hot plate welding machine mold is divided into horizontal and vertical movement.

2. The volume of the equipment depends on the size of the welding parts.

3. According to the size of the equipment, the drive mode can be pneumatic, hydraulic drive or servo motor drive.

4. According to the requirements of the welding procedure, semi-automatic or fully automatic mode can be selected.

5. The equipment maintains good stability, which can ensure consistent welding effect and high accuracy of the workpiece after processing.

6. Welding temperature, heating time, cooling time, heating depth, welding depth pressure, switching time and other parameters are all adjustable, and other selective welding parameters are also adjustable.

7. For equipment with a horizontal hot plate design, the hot plate can be rotated 90° for cleaning.

英语

英语 日语

日语 中文简体

中文简体