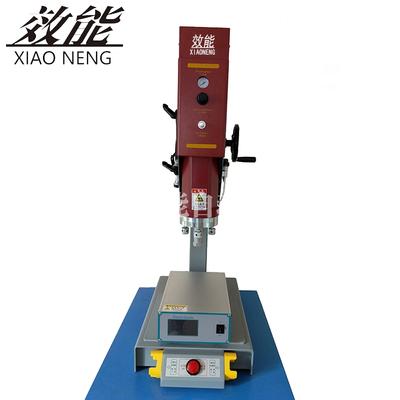

A Beginner’s Guide to Plastic Hot Plate Welding Machines

Plastic hot plate welding machines are essential tools for joining thermoplastic materials. They are used in a variety of industries, including automotive, medical, and packaging. If it is your first time learning about hot plate machines, this guide will provide you with all the information you need to get started.

What is Plastic Hot Plate Welding?

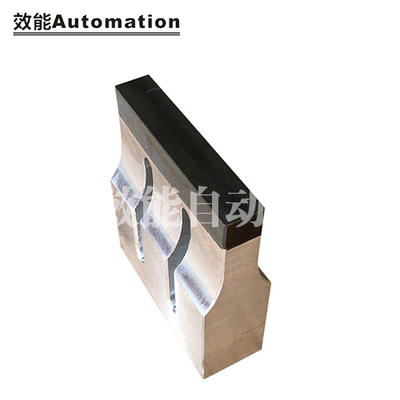

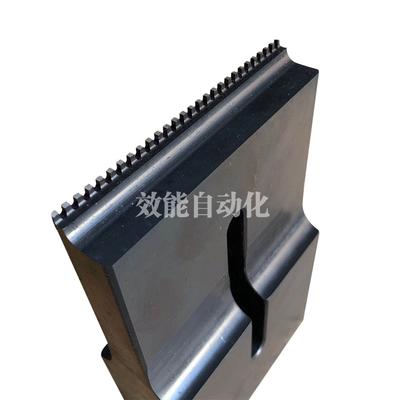

Plastic hot plate welding is a process that involves heating two plastic parts using a hot plate until they melt and fuse together. The process is used to join thermoplastic materials, such as polyethylene, polypropylene, ABS, GF and mixed materials. The hot plate welding machine is used to heat the plastic parts to a specific temperature, which is usually between 100°C and 500°C. Once the plastic parts are heated, they are pressed together and held in place until they cool and solidify.

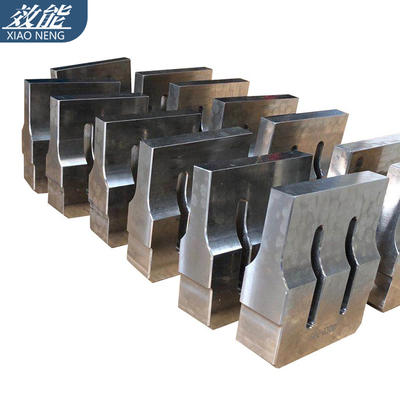

Types of Plastic Hot Plate Welding Machines

There are two main types of plastic hot plate welding machines: manual and automatic. Manual machines require an operator to place the plastic parts on the hot plate and press them together. Automatic machines, on the other hand, use a robotic arm to place the plastic parts on the hot plate and press them together. Automatic machines are more efficient and are used in high-volume production environments.

Choosing the Right Machine

When choosing a plastic hot plate welding machine, there are several factors to consider. These include the size of the machine, the type of plastic parts you will be welding, and the production volume. It is important to choose a machine that is the right size for your needs. If you will be welding large parts, you will need a machine with a large hot plate. If you will be welding small parts, a smaller machine will suffice.

The type of plastic parts you will be welding is also important. Some plastics are more difficult to weld than others, and some plastics require higher temperatures than others. It is important to choose a machine that is capable of welding the types of plastics you will be working with.

Finally, the production volume is an important factor to consider. If you will be welding a large number of parts, you will need a machine that is capable of handling high-volume production.

Safety Considerations

When working with plastic hot plate welding machines, it is important to take safety precautions. The hot plate can reach temperatures of up to 500°C, which can cause serious burns. Always wear gloves and protective clothing when working with the machine. It is also important to ensure that the machine is properly grounded to prevent electrical shocks.

Conclusion

Plastic hot plate welding machines are essential tools for joining thermoplastic materials. They are used in a variety of industries and can be manual or automatic. When choosing a machine, it is important to consider the size of the machine, the type of plastic parts you will be welding, and the production volume. Always take safety precautions when working with the machine to prevent burns and electrical shocks.

英语

英语 日语

日语 中文简体

中文简体