Hot plate welding is a widely used technique for joining thermoplastics in various industries. In recent years, advancements in hot plate welding machine technology have propelled this method to new heights. This article aims to explore the latest innovations and benefits of hot plate welding machines, showcasing how they have revolutionized the welding process.

1. Intelligent Control Systems:

State-of-the-art hot plate welding machines are equipped with intelligent control systems that offer advanced functionality and ease of operation. User-friendly interfaces with intuitive touchscreens allow operators to set and monitor key parameters accurately. The integration of programmable logic controllers (PLCs) enables automated control and real-time data acquisition, ensuring optimal process control and traceability.

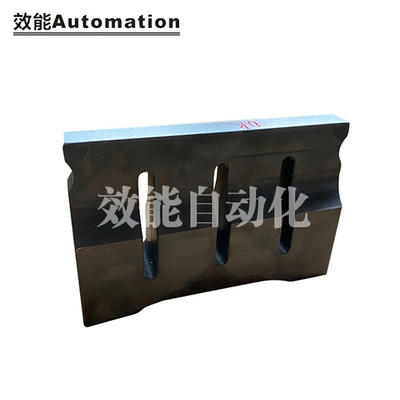

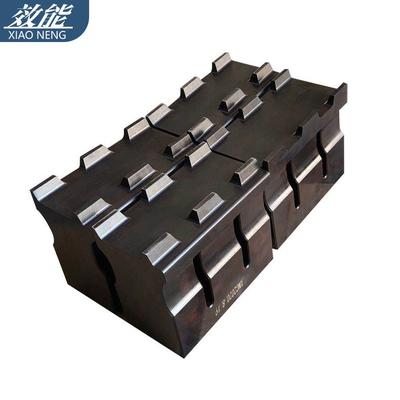

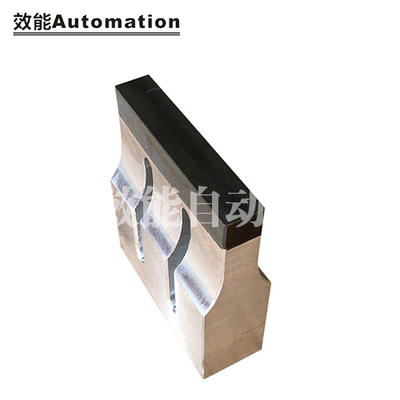

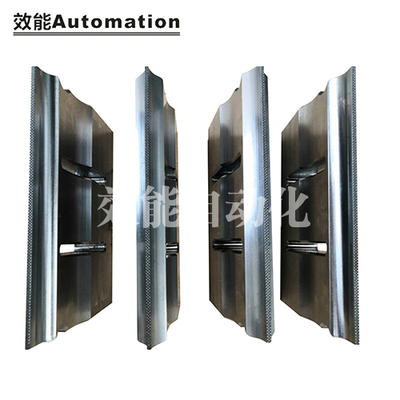

2. Customization and Flexibility:

Advancements in hot plate welding machine design have facilitated greater customization and adaptability to meet specific industry requirements. Modular machine structures and interchangeable tooling systems enable quick changeovers and the ability to handle various part sizes and geometries. This flexibility allows manufacturers to streamline production and respond swiftly to evolving market demands.

3. Process Monitoring and Quality Assurance:

To ensure weld integrity and consistency, modern hot plate welding machines incorporate advanced monitoring systems. These systems can detect irregularities in temperature and force during the welding process. Real-time feedback and automatic adjustments help maintain optimal process conditions, minimizing defects and improving overall weld quality. Additionally, data logging and analysis capabilities enable comprehensive quality assurance and process optimization.

4. Integration with Industry 4.0:

The integration of hot plate welding machines with Industry 4.0 concepts has unlocked new possibilities for connectivity and automation. These machines can be seamlessly integrated into smart manufacturing environments, enabling real-time production monitoring, remote diagnostics, and predictive maintenance. Such integration enhances overall efficiency, reduces downtime, and enables data-driven decision-making.

Advancements in hot plate welding machine technology have transformed the welding process, offering enhanced heating efficiency, intelligent control systems, customization options, improved process monitoring, and seamless integration with Industry 4.0. As a result, manufacturers across industries can benefit from increased productivity, higher quality welds, and greater flexibility in their production processes. Embracing these cutting-edge advancements in hot plate welding machines is key to staying competitive in today's rapidly evolving manufacturing landscape.

英语

英语 日语

日语 中文简体

中文简体