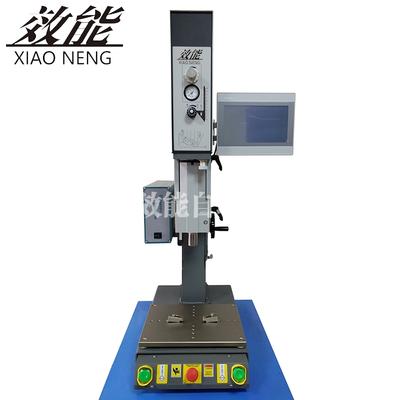

Choosing the right plastic hot plate welding machine for your production needs is crucial to ensure that you achieve the desired results. With so many options available in the market, it can be overwhelming to make the right decision. In this article, we will discuss the key factors that you should consider when choosing a plastic hot plate welding machine.

Firstly, it is important to determine the type of plastic that you will be welding. Different types of plastic have different melting points, and this can affect the type of hot plate welding machine that you need. The temperature of hot plate machine is 0-500℃. It is important to check the melting point of the material in advance

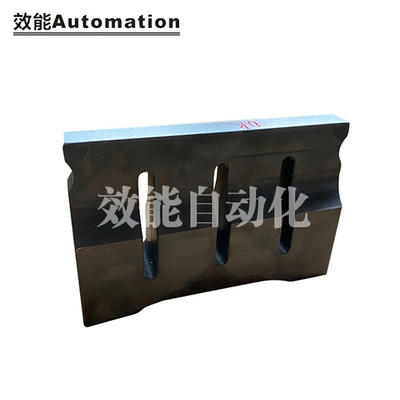

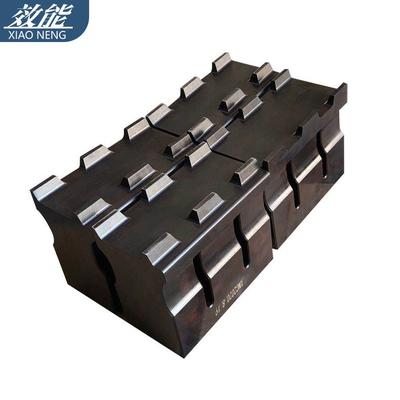

Secondly, you should consider the size of the plastic parts that you will be welding. If you will be welding large parts, you will need a hot plate welding machine with a large heating surface. On the other hand, if you will be welding small parts, you can opt for a smaller hot plate welding machine. The largest welding machine to weld plastic pallets.

Thirdly, you should consider the level of automation you need. If you have a large volume of production, you may want to consider a fully automated hot plate welding machine. This type of machine can work with a robotic arm to perform all the necessary tasks, including loading and unloading parts, and can significantly increase your production efficiency.

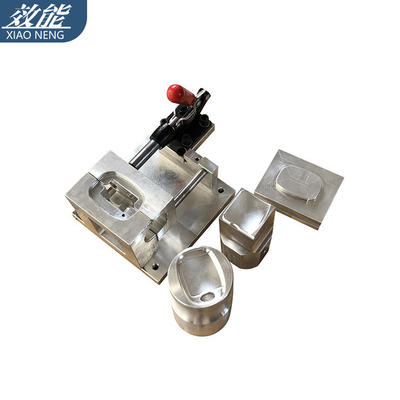

Fourthly, you should consider the level of precision that you require. If you need to achieve a high level of precision in your welding, you should consider a hot plate welding machine with a digital temperature control system. This will allow you to precisely control the temperature of the hot plate, ensuring that you achieve consistent and accurate results.

Fifthly, you should consider the level of flexibility you need. If you need to weld different types of plastic parts, you should consider a servo motor driven hot plate welding machine that can handle different types of plastic.

Finally, you should consider the cost of the hot plate welding machine. While it may be tempting to opt for a cheaper machine, you should consider the long-term costs and benefits. Investing in a high-quality hot plate welding machine may initially cost more, but it can save you money in the long run by reducing the need for repairs and maintenance.

In conclusion, choosing the right plastic hot plate welding machine for your production needs requires careful consideration of several factors, including the type of plastic, the size of the parts, the level of automation, the level of precision, the level of flexibility, and the cost. By considering these factors, you can ensure that you make the right decision and achieve the desired results in your plastic welding production.

英语

英语 日语

日语 中文简体

中文简体