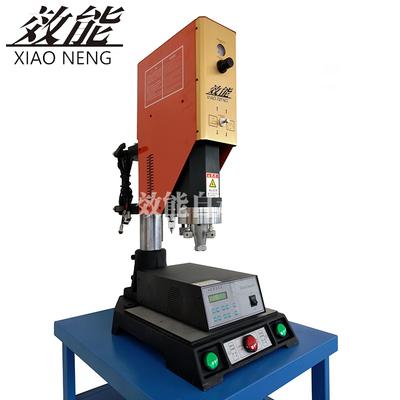

Plastic hot plate welding machines are essential for many industries, including automotive, medical, and packaging. These machines are used to join plastic parts together by melting and fusing them with a hot plate. To ensure the optimal performance of your plastic hot plate welding machine, proper maintenance is crucial. In this article, we will discuss how to properly maintain your plastic hot plate welding machine.

- Regular Cleaning

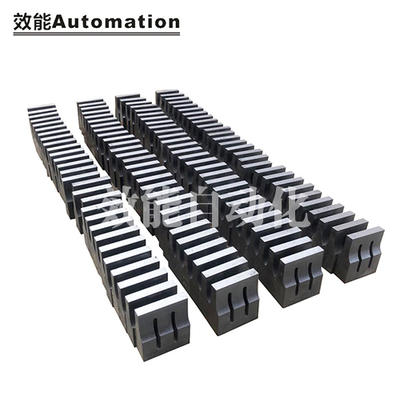

One of the most important aspects of maintaining your plastic hot plate welding machine is regular cleaning. Over time, plastic residue and debris can accumulate on the hot plate, which can affect the quality of the weld. To prevent this, you should clean the hot plate regularly using a non-abrasive cleaning solution and a soft cloth.

- Lubrication

Another important aspect of maintenance is lubrication. The moving parts of your plastic hot plate welding machine should be lubricated regularly to ensure smooth operation. Use a high-quality lubricant that is recommended by the manufacturer to avoid damaging the machine.

- Inspection

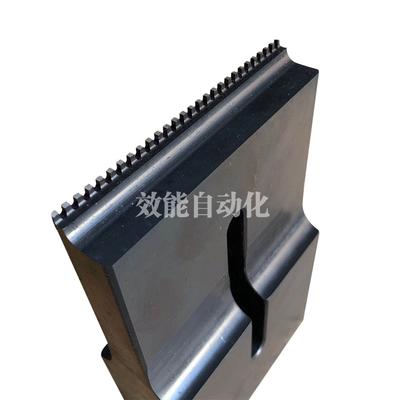

Regular inspection of your plastic hot plate welding machine is also crucial. Check for any signs of wear and tear, such as cracks or rust. If you notice any damage, replace the damaged parts immediately to prevent further damage to the machine.

- Calibration

Calibration is another important aspect of maintaining your plastic hot plate welding machine. Over time, the temperature and pressure settings of the machine may become inaccurate, affecting the quality of the weld. To ensure optimal performance, you should calibrate your machine regularly according to the manufacturer’s instructions.

- Training

Proper training is essential for maintaining your plastic hot plate welding machine. Ensure that all operators are trained on how to use and maintain the machine properly. This will not only help to prevent damage to the machine but also ensure that the machine operates at optimal performance.

In conclusion, proper maintenance of your plastic hot plate welding machine is essential for optimal performance. Regular cleaning, lubrication, inspection, calibration, and training are all necessary to ensure that your machine operates at its best. By following these maintenance tips, you can extend the lifespan of your machine and ensure that it continues to produce high-quality welds for years to come.

英语

英语 日语

日语 中文简体

中文简体.jpg?imageView2/2/format/jp2)