Meta-description: Discover the incredible potential of the hot plate welding machine, a cutting-edge technology that revolutionizes the process of joining materials. Find out how this innovative device works, its applications across industries, and the benefits it offers.

## Introduction ##

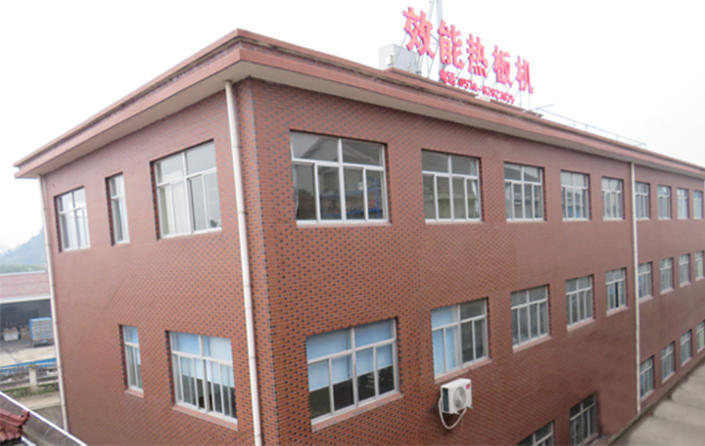

In today's rapidly evolving world, where precision and efficiency are paramount, technological advancements have become imperative. The hot plate welding machine, a state-of-the-art joining technology, has emerged as a game-changer. This article explores the functionalities, applications, and advantages that this innovative device brings to various industries.

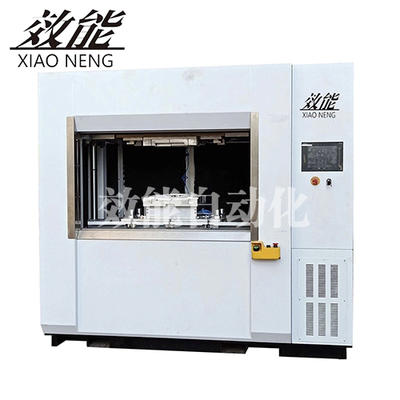

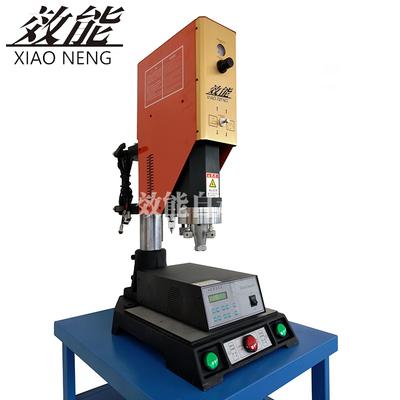

## What is a Hot Plate Welding Machine? ##

The hot plate welding machine is a sophisticated device that utilizes heat to join thermoplastic materials. This process involves heating the surfaces of the materials to be joined using a hot plate, applying pressure to fuse them together, and then cooling the welded part to solidify the bond.

### How Does it Work? ###

The hot plate welding machine operates in a series of steps:

1. Preparation: The two materials to be joined are positioned on the machine's work area, precisely aligned.

2. Heating: The hot plate, usually made of aluminum, is heated to the desired temperature. It is crucial to select the appropriate temperature, as it varies according to the materials being welded.

3. Melting: The heated plate is brought into contact with the surfaces of the materials. As the heat penetrates, the thermoplastic materials melt to a specific depth, forming a molten layer.

4. Joining: The molten region is pressed firmly together, resulting in a seamless and strong bond. The pressure is maintained for a specific duration to ensure a reliable weld.

5. Cooling: After the joining process, the hot plate is removed, and the welded assembly is cooled using various methods to solidify the bond.

### Applications of the Hot Plate Welding Machine ###

The versatility and efficiency of the hot plate welding machine make it indispensable in numerous industries. Here are some noteworthy applications:

1. Automotive Industry: The hot plate welding machine is extensively utilized in automotive manufacturing to join complex plastic parts such as engine coolant tank, engine pipe and dashboard assemblies. This precise and reliable joining technique ensures structural integrity and increases vehicle safety.

2. Electrical and Electronics: From connecting wiring harnesses to assembling intricate electronic devices, the hot plate welding machine plays a significant role in this sector. Its ability to join dissimilar materials and intricate shapes makes it an ideal choice for industries involved in the production of electrical appliances and electronic components.

3. Packaging Industry: In the packaging industry, the hot plate welding machine is utilized to create air-tight seals on plastic containers, ensuring product freshness and containment. This technology enables efficient packaging assembly lines, reducing production time and costs.

4. Medical Devices: The hot plate welding machine demonstrates exceptional precision and cleanliness in the medical industry. It is used to join components of medical devices, ensuring reliability and maximizing patient safety. The machine's capability to bond intricate geometries without compromising cleanliness standards is particularly valuable in this field.

## Benefits of Using a Hot Plate Welding Machine ##

The hot plate welding machine offers a plethora of advantages over traditional joining techniques. Here are some key benefits:

1. Enhanced Strength: The hot plate welding process creates strong and durable bonds. The fusion of the molten regions ensures that the joint is as robust as the original material, minimizing the risk of breakage or failure.

2. Design Freedom: This technology allows the joining of different shapes, geometries, and materials, providing designers and manufacturers with innovative freedom. It enables the creation of complex structures that were previously challenging to join.

3. Cost-Effective: The hot plate welding machine offers cost savings through reduction in material usage, fast production cycles, low maintenance requirements, and high efficiency. The elimination of additional fasteners or adhesives further reduces assembly costs.

4. Environmental Sustainability: Unlike adhesives or solvents involved in other joining techniques, the hot plate welding process does not introduce additional chemicals to the environment, making it an environmentally friendly option. It reduces waste and contributes to sustainable manufacturing practices.

## Frequently Asked Questions (FAQs) ##

Q: Can the hot plate welding machine join materials of different thicknesses?

A: Yes, the hot plate welding machine can effectively join materials of different thicknesses. The welding process allows for varying heat application, ensuring a consistent and reliable bond.

Q: Is the hot plate welding technique suitable for joining complex shapes?

A: Absolutely! The hot plate welding machine excels in joining even the most intricate shapes. Its versatility makes it a preferred choice for industries that require complex geometries to be joined.

Q: What maintenance is required for the hot plate welding machine?

A: The hot plate welding machine requires minimal maintenance. Regular cleaning and occasional inspection of the hot plate for wear and tear are recommended to ensure optimal performance.

## Conclusion ##

The hot plate welding machine has undoubtedly redefined the joining process, offering unparalleled advantages to a wide range of industries. From automotive and electronics to packaging and medical devices, this innovative technology promises increased strength, design flexibility, cost savings, and environmental sustainability. Embracing this cutting-edge machine opens the doors to endless possibilities and sets new industry standards. Are you ready to revolutionize your joining techniques with the hot plate welding machine?

英语

英语 日语

日语 中文简体

中文简体